Description:

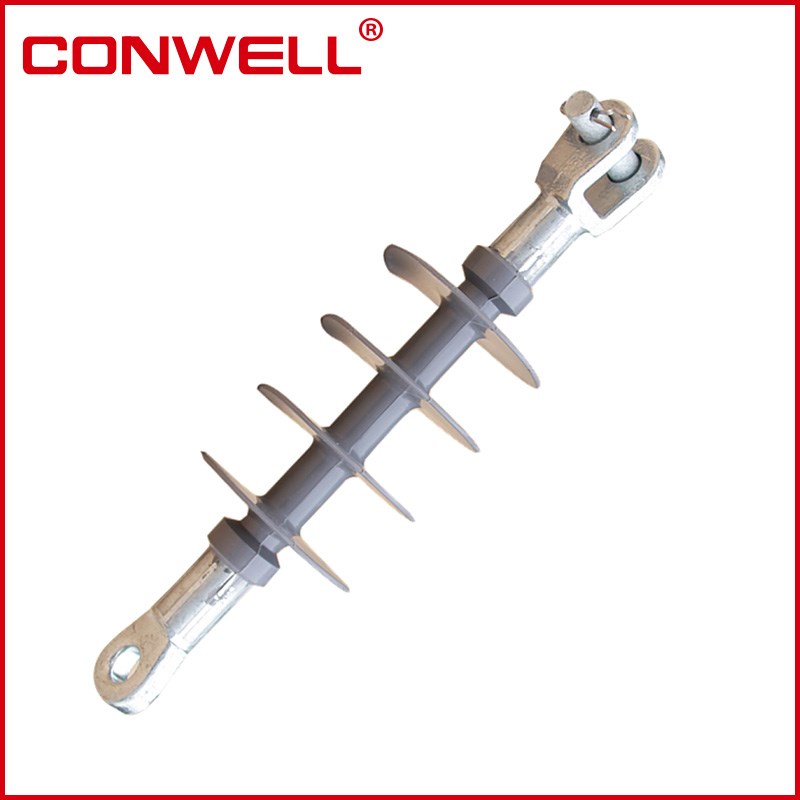

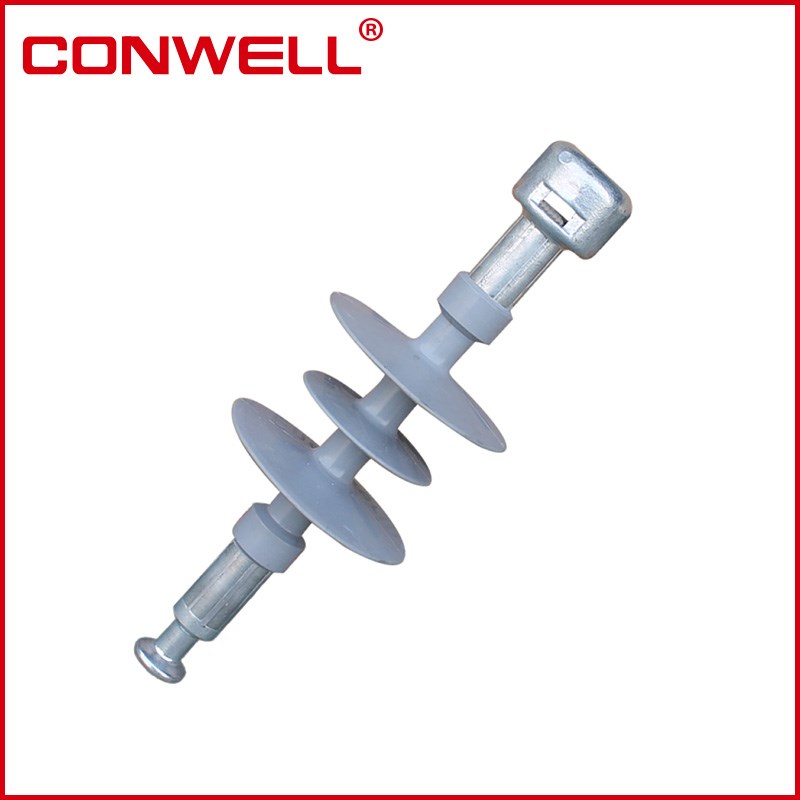

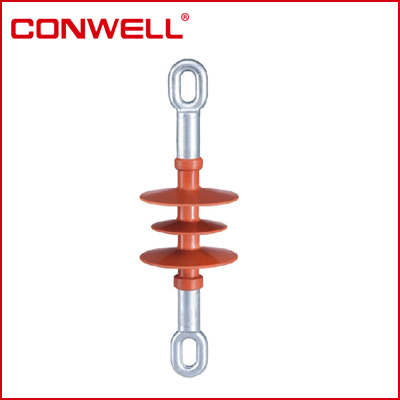

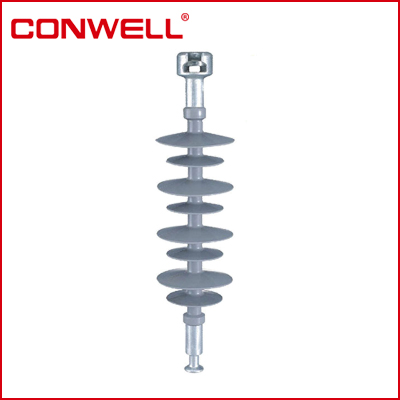

The Polymer Insulator are made of glass fiber epoxy core rod, silicone rubber shed and metal fittings.

The silicon rubber shed adopt the whole packing pressure technique, and then to solve the key probleminterface electric spark puncture, which would affect the reliability of composite insulator.Connection of the glassfiber rod and metal fittings, adopts the pressure welding technique of the international advanced level, and have the full automatic sound wave detection of defects system, high intension, beautiful outline, small volume, light weight, and the metal fitting of galvanization can corrosion prevention and exchange used with porcelain insulator.

Technical Data:

|

Code |

Rated Voltage (kV) |

Breaking Load (kN) |

Length |

Insulation Height |

Creepage Distance |

Unbrella Diameter |

1min power frequency wet withstand voltage |

Full wave lightning impluse withstand voltage |

|

(kV) |

(kN) |

(mm) |

(kV) |

|||||

|

FPQ-24/4 |

24 |

4 |

335 |

273 |

655 |

146/112 |

60 |

125 |

|

FPQ-24/6 |

24 |

6 |

310 |

210 |

535 |

120 |

60 |

125 |

|

FPQ-36/5 |

36 |

5 |

450 |

340 |

950 |

145/115 |

95 |

230 |

|

FXBW2-12/70UD |

12 |

70 |

350 |

180 |

360 |

98/88 |

95 |

105 |

|

FXB2-15/70UD |

15 |

70 |

275 |

200 |

470 |

98/88 |

42 |

105 |

|

FXB2-24/70UD |

24 |

70 |

430 |

290 |

680 |

98 |

42 |

150 |

|

FXB2-28/70UD |

28 |

70 |

430 |

290 |

680 |

98 |

95 |

230 |

|

FXB2-33/70UD |

33 |

70 |

550 |

360 |

720 |

98 |

95 |

230 |

|

FXB2-35/70UD |

36 |

70 |

570 |

400 |

1000 |

76 |

95 |

230 |

|

FXBO2-36/70 |

36 |

70 |

650 |

450 |

720 |

98 |

95 |

230 |

Application

EN

EN

CN

CN